Types of Hydraulic Pumps

페이지 정보

작성자 Florence Seymor… 작성일24-10-13 07:53 조회4회 댓글0건관련링크

본문

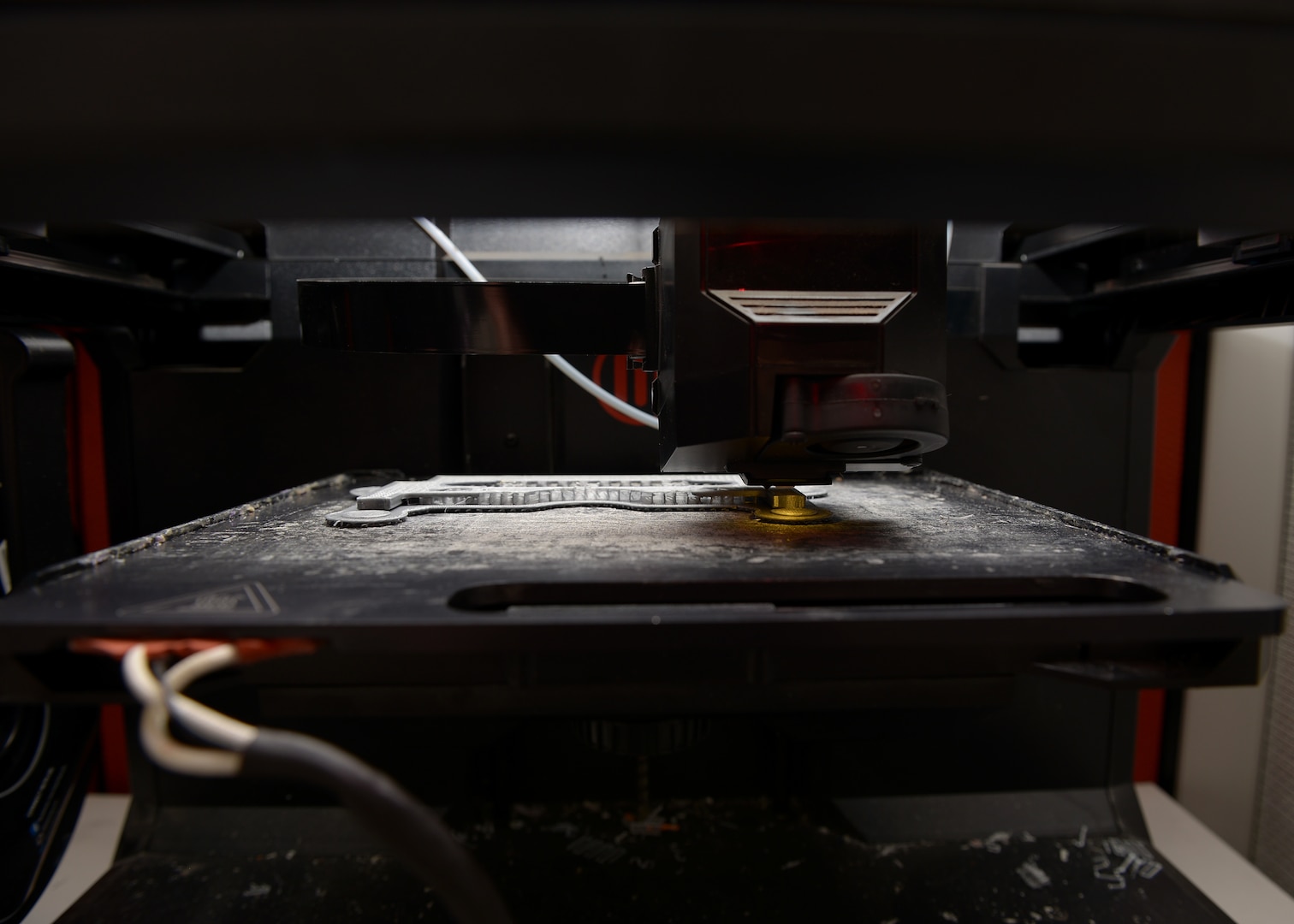

Reside Pak pumps are additionally primarily used on refuse equipment and are engine crankshaft pushed; however, the inlet on a Dwell Pak pump is just not outfitted with a shut-off valve. With a Dwell Pak pump, the outlet incorporates a circulate limiting valve. This is known as a Reside Pak valve. The valve acts as an unloading valve in OFF mode and a circulation limiting valve within the ON mode. Consequently, the hydraulic pumps system velocity is proscribed to maintain within protected operating parameters. As the title implies, these pumps employ gears to maneuver the fluid through the pump. Primary Construction: At its core, a gear pump consists of two meshing gears enclosed in a casing. One gear is the driving gear (hooked up to the drive mechanism) whereas the other is the pushed gear. Operation: As these gears rotate, their meshing action creates a vacuum at the pump inlet, drawing in hydraulic fluid.

Its most important operate is to create the movement of oil under strain via the whole hydraulic system and therefore to help the switch of energy and movement (i.e. helpful work). Direction control valves/Stream control valves/ Strain Relief Valves (Fluid Controlling Components): These valves are fitted in hydraulic system at particular places. A pilot line in each representation and operate uses hydraulic vitality to sign or operate other valves. Studying to comprehend pilot lines is essential to understanding advance hydraulic schematics. As a drain line, the dashed line merely represents any component with leakage fluid needing a path represented within the drawing. This implies the same volume of movement is produced with each rotation of the pump’s shaft. Gear pumps are rated in terms of the pump’s maximum stress score, cubic inch displacement, and maximum input pace limitation. Four forms of gear pumps exist Inner gear pumps, Lobe pumps, Exterior gear pumps, and Gerotor pumps. Exterior Gear Pumps: Exterior Gear pumps depend on the counter-rotating movement of meshed exterior spur gears to impart movement to a fluid. There are two kinds of tank schematics: pressurized and unpressurized. Unpressurized is unquestionably most prevalent in the market. One can infer that the pressurized tank is the one that is enclosed. With a reservoir, you can even point out if you want oil to be returned above (top) or under (bottom) the oil level within the tank.

Plus, the hoses, fittings, seals, and connections guarantee every part works together seamlessly. HoseBox understands the intricacies of hydraulic techniques and the important role of every component in attaining optimum efficiency. As such, we’ve devoted our experience to crafting excessive-high quality hydraulic kits and parts, offering you with the reliability and efficiency you need. Though pump failure has been unpredictable up to now, new diagnostic technologies proceed to improve on detection strategies that beforehand relied upon vibration signals alone. Measuring discharge pressures allows manufacturers to extra accurately predict pump wear. Discharge sensors will be simply integrated into current systems, including to the safety and versatility of the hydraulic pump. Instead of utilizing a linear cylinder, a hydraulic motor uses pressure to rotate itself. There are numerous types of hydraulic motors accessible. A couple of widespread examples embrace axial piston motors, radio piston motors, hydraulic gear motors, and hydraulic vane motors. A hydraulic motor is a durable option that may last a very long time as long as it's taken care of appropriately.

댓글목록

등록된 댓글이 없습니다.

(주)해성동기와

(주)해성동기와